Order Tracking of Gear Mesh Vibration in a Speed Reducer: A Comprehensive Study

Overview of Gear Vibration Challenges

This study focuses on the reproduction and analysis of the vibration characteristics of a speed reducer incorporating a planetary gear set. Using advanced computer simulation techniques, we aimed to identify resonance conditions dependent on the number of revolutions and meshing frequencies. By comparing simulated data with experimental results, we evaluated the feasibility of using virtual models for early-stage development. Our findings confirm that virtual models can effectively replicate the vibration characteristics of physical systems, thus offering potential for reducing development time and costs.

Understanding the Importance of Gear Mesh Vibration in Speed Reducers

Advanced Techniques for Gear Vibration Analysis and Order Tracking

1. Analytical Foundation

The initial step involved determining the gear meshing frequency using a formula based on the specifications of the speed reducer gear set. This provided a theoretical basis for identifying potential resonance conditions.

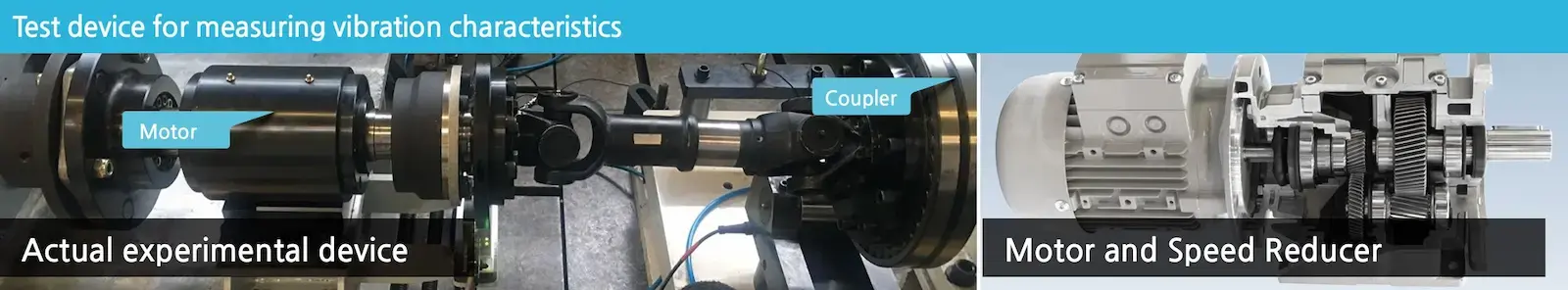

2. Experimental Setup

A physical speed reducer, including the planetary gear set, was mounted on a dynamo equipped with an accelerometer and microphone for precise vibration measurement. The system was accelerated from a stationary state to a designated RPM, and the transient vibration characteristics were recorded.

3. Simulation Model

A 3D dynamic model of the speed reducer was constructed using RecurDyn software. The model incorporated several key technologies:

- Flexible Body Modeling: This accounted for the deformation of the housing and shaft, ensuring accurate measurement of surface vibrations.

- Specialized Gear Contact Algorithm: This provided precise analysis of gear interactions.

- High-Speed Flexible Body Technology (RFlex): Improved simulation performance by using mode shapes of the housing instead of the entire DOFs of the nodes.

4. Simulation Execution

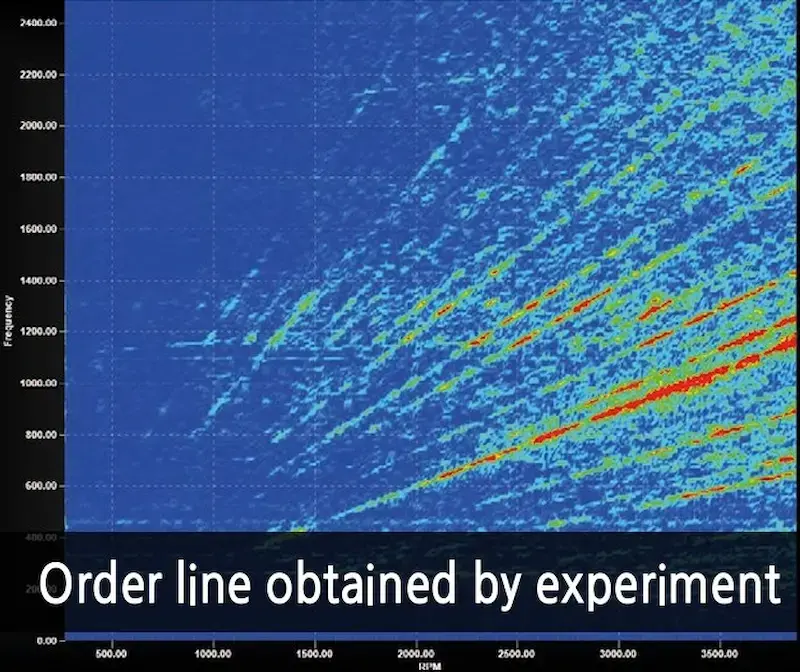

Simulations were run under the same conditions as the physical experiments. The transient vibration characteristics were analyzed, focusing on the Campbell diagram, which illustrates the order lines and their tendencies.

5. Validation

The results from the simulation were compared with the experimental data and theoretical predictions to validate the accuracy of the virtual model.

Key Outcomes from Gear Vibration Analysis and Optimization

The simulation successfully reproduced the vibration characteristics observed in the physical experiments. The Campbell diagram results, including order lines and their tendencies, matched closely with experimental data, confirming the validity of the virtual model for vibration analysis.

Insights and Solutions for Gear Vibration Challenges in Speed Reducers

The ability to accurately simulate the vibration characteristics of a speed reducer has significant implications for the design and development process. By identifying resonance conditions and potential issues early in the development stage, manufacturers can reduce reliance on physical prototypes, thereby saving time and cost.

The specialized gear and bearing UI, along with the flexible body modeling techniques used in this study, demonstrated high accuracy in dynamic simulations. The intuitive Campbell diagram UI facilitated efficient order tracking analysis, further enhancing the usability of simulation technology in practical applications.

Achieve Reliable and Efficient Systems with Expert Gear Vibration Analysis

This study confirmed the potential of using virtual models for vibration analysis of speed reducers, particularly those incorporating planetary gear sets. The validated simulation model can serve as a reliable tool for early-stage development, offering a cost-effective alternative to physical testing. Future research may explore further refinements in simulation techniques and their application to more complex gear systems.